Food Safety

Our Stock Chiller™ products are designed with food safety in mind. By improving food safety, the following attributes can be improved in the kitchen:

- food product quality

- food product consistency between batches

- food product shelf life

- kitchen and staff hygiene

Ultimately, improving these attributes will improve customer satisfaction with your service, reduce spoiled food waste, reduce food borne illness, and reduce the incidence of costly local health department demerits, fines, and closures.

Rapid Liquid Chilling: Minutes, Not Hours

The Stock Chiller™ rapid soup and stock chilling system uses a patented process to lower the temperature of hot liquids such as soups, stocks, and sauces effectively and consistently. For example, the chill time using our Stock Chiller™ units and containers for a 5 gallon batch of soup stock from 190°F to 40°F (88°C to 5°C) could be as short as 6 minutes.

With such rapid chill times, the total time the chilling food spends in the temperature danger zone is kept to a minimum. According to the USDA and FDA which determine the Hazards Analysis and Critical Control Point (HACCP) guidelines, the temperature danger zone is the temperature range between 41°F and 140°F (5°C to 60°C) where food borne bacteria can grow to dangerous levels that can cause illness. In conjunction with other HACCP practices, keeping the time in the temperature danger zone to a minimum reduces the food borne microorganisms and improves shelf life for the chilled food product.

Typical Chill Times

Water-Based Soups and Stocks

SC01 – Freestanding Unit

| 2 Gallon (7.5 L) | 4 minutes |

| 5 Gallon (18.7 L) | 6 minutes |

SC02 – 5 Gallon Countertop Stock Chiller Units

| 5 Gallon (18.7 L) | 8 minutes |

SC03 – 2 Gallon Countertop Stock Chiller Units

| 2 Gallon (7.5 L) | 6 minutes |

Thicker Liquid Foods (Cream Soup / Red Sauce)

SC02 – 5 Gallon Countertop Stock Chiller Units

| 5 Gallon (18.7 L) | 10-15 minutes |

SC03 – 2 Gallon Countertop Stock Chiller Units

| 2 Gallon (7.5 L) | 8-12 minutes |

Even Thicker Liquid Foods (Demi Gloss / Salsa)

SC02 – 5 Gallon Countertop Stock Chiller Units

| 5 Gallon (18.7 L) | 15-20 minutes |

Very Thick Liquid Foods (Cheese Sauce / Chili / Thick Salsa)

SC02 – 5 Gallon Countertop Stock Chiller Units

| 5 Gallon (18.7 L) | 20-30+ minutes |

Note: chill times vary depending on the thickness and composition of the liquid being chilled. Thicker liquids typically take longer to chill.

Sanitary Handling

“Conventional methods” used throughout the food industry for chilling hot liquid foods through the temperature danger zone were not originally designed for processing large batches and typically involve handling steps that risk the introduction of contamination or improper food handling. These methods include chilling liquids in shallow pans in a fridge or blast chiller, using uncovered pots in ice water baths, and dipping ice paddles into pots of food. Are you using these methods currently?

The Stock Chiller™ rapid liquid chilling process was designed with sanitation in mind. Liquid food products are kept sealed in our containers during the chilling process and can be moved directly to cold storage in the same containers, reducing steps that require direct handling of the food product and eliminating the risk of contamination. Combined with rapid chill times, the Stock Chiller™ system is the ultimate solution for safe, quick, and sanitary liquid food chilling and storage.

NSF Certification

Our Stock Chiller™ Units and Containers have been certified by NSF to conform to NSF/ANSI Standard 169. Our chilling units bear the NSF mark. Learn more about the National Sanitary Foundation and its certifications here [nsf.org].

HACCP Compliance

We work with our customers to implement Hazards Analysis and Control Point Planning (HACCP) when deploying Stock Chiller™ systems.

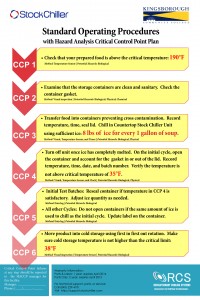

As a service, we work with our customers to provide custom Stock Chiller™ system HACCP-related signage for use kitchens as a visual reference. Signs are tailored to the customer’s needs, internal management processes, and local health codes. The image to the right shows a HACCP poster that was developed for a kitchen in a culinary arts training program at Kingsborough Community College.

Learn more about the Food and Drug Administration’s HACCP guidelines and recommendations for retail and food service here [fda.gov].

Kitchen Culture and Training